字體:小 中 大

字體:小 中 大 |

|

|

|

| 2012/05/24 15:49:34瀏覽481|回應1|推薦0 | |

There was a soundless TAIPEI MOTOR SHOW held from last Christmas to 3rdJanuary 2010. Thanks for the over-50% sales shrinkage from annual 500 thousand vehicles to 200 thousand ones, this time the biggest biannual motor show in this island premieres only 2 new models namely a Luxgen 7 SUV and a CMC e-moving electric motorcycle, 2 mainland-China Makes Geely and Chery, and a beautiful Lexus LFA crystal unit although it’s a laser sculpture rather than a motor actually. Even the sales-orders taken in exhibition lot which usually seen in motor shows in South-eastern Asia countries has reduced over 60% compared to the past, only the locally-built Make Luxgen claimed that it got over 100 orders.

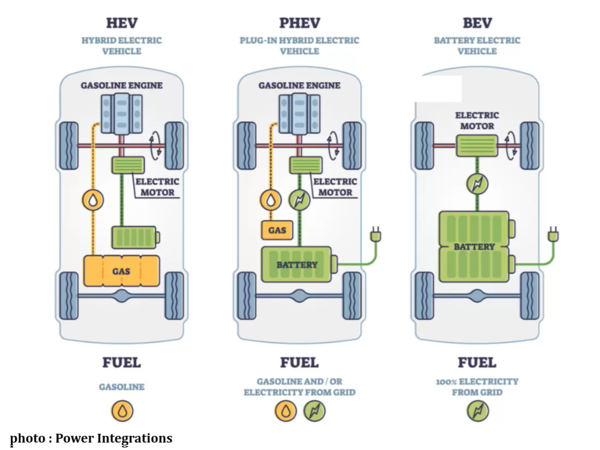

See the world from a particle of sand. Under pressures of fossil-energy shortage and greenhouse effect, does it mean that global automotive market except China , India and Brazil bubbles with cars crowded but no fuels and roads might face a glacial period rather than a freezing winter? The truth may not be so pessimistic as the car sales in developed countries but can not be expected with jumping growth in China . Even severely challenged by aircraft, high-speed railway, underground express, bus, scooter, bicycle, etc., car has proven itself to be an optimized door-to-door personal carrier by its safety, comfort, time-saving and reasonable cost. As long as human being exists, the great demand of cars do as well. But the automotive industry meets 3 key barriers in the forthcoming decade, the auto-industry conquerors will be rewarded by overbalance growth, and the losers could be evaporated from the battle field. The 1st barrier comes from the deliberate unconsciousness of automotive industry, at least most ones in this industry, regarding the environment responsibility to earth. This industry relies on lots of petroleum and mineral resources to produce variety of components, and re-processes them by consuming huge energy and with discharging organic solvents, metal powders and other poisons. Vehicles in lifetime keep exhausting CO2, NOx, PAH, etc.. If looking at the top-4 divisions generating greenhouse gases – energy, manufacturing, stockbreeding and transportation, the automotive industry involves heavily with 3 of them. This defendant continues production expansions worldwide but undertakes deeply asymmetric energy-saving and carbon-reduction duties by carrot-and-sticks of its employee totals, GDP proportion, government-hold or chartered identity. Enormous carbon footprints engrave heavily in the idle facilities between the global 80-million production capacity and the only 50-million sales, but we see soap-opera every day that Toyota , VAG, GM and Hyundai are busy at expansion and fight for the world No. 1. Governments should give this industry a punch to grow up from an effective manufacturer to a self-disciplined one. The 2nd barrier is the cost and work-done issues of the commoditizing technologies regarding cars adopting clean energy. Among the potential candidates, hydrogen fuel-cell still faces mass production, transportation, and safety-storage problems. Implementing the fueling chain from hydrogen plant, gas station, alloy-grabbing hydrogen steel-bottles in cars, to the durable hydrogen fuel-cell battery system indicates an industrial revolution rather than a renovation which requires 20 years even longer for folks. ZOE (Zinc-oxide) fuel-cell battery, just walking out the laboratory and seen in 2009 FRANKFURT MOTOR SHOW, is hard to list a cost estimation and time table. PEV (pure electricity vehicle) seems get everything done but battery. Current battery technologies, already good job for a lap-top but a muck for a car, performs industrial-average 100 watt-hour/kg, max mileage reaching 150 km , recharging life of 2,000 times. It sounds not so bad that 10 years will allow the batteries enhanced to 300 Wh/kg and recharging 3,000 times under reasonable commodity cost. Unfortunately the decisive challenge is the deposit shortage of lithium and rare-earth elements e.g. neodymium, which are the key components in battery and electric motor now matter in PEV, lap-top, mobile phone, air conditioners, etc.. The 3rd barrier will occurs in building an enduring recycling value-chain. It indicates automotive industry has to upgrade itself from a self-disciplined suplier to a responsible one. What happened in selected developed countries in latest decades told us, the recycling industry dealing with the carcass of the tones-weighted mechanical beast costs not-enough efficiency, gangsters, and second pollution, especially unprocessed garbage shipped out and abandoned in African countries under the name of ‘used metal or computer parts’. According to the scrap-amount total and the pollution degree, the automotive industry can not be blamed as top criminal prior than home electricity, computer, and communication products, but it is the easiest one to be monitored and supervised from development beginning to retiring end by governments due to limited Makes from its oligopoly-market characteristic and full-ownership tracking from license and number-plate registration. As an extreme threaten, the auto Makes could be obliged by governments to recycle respondent vehicle-scraps for production or import quota. As opportunities, the recycling business foretells profit potentiality, and the automotive industry can be removed from the black list of environmental groups and benchmarked as welcome green products for bringing lost young-generation customers back. Passing through the birth pang before hugging the dawn light of automotive industry in the coming decade, guidelines and directions for winners might read as follows: A. Hybrid vehicles to be mainstream dominating the market. But it might not be a good news for product-leading Toyota using parallel-connection hybrid , because the winner could a kind of the series-connection hybrid installed in Mercedes S400h which its electricity power only offers engine-quick-start and extra torque in acceleration and re-acceleration. The greatest advantage of Mercedes-style system is the car price only increased by 10%, compared to 40% of Toyota-style one. Accord to the 3 basic defects of internal-combustion engine, namely fuel consuming in idling, high pollution of incomplete burning within rev changes, and useless heat from 60% of combustion energy, the Mercedes system shoots the idling and a part of rev-change pollution. When battery efficiency moves on, the electric power in this series-connection hybrid will expand its serving range and time until ultimately ideal status that the internal-combustion unit acts as a pure electricity generator in constant rpm. When hybrid system havs such a constant-rpm engine, the hybrid decade can be glorified as mature enough to be bridged between internal-combustion era and the forthcoming hydrogen-fuel-cell or PEV era.

B. Minivans built upon sandwich body-chassis rule the market tomorrow. Sandwich body-chassis, fitted transmission and suspension mechanics in 1st layer, power train in 2nd layer and cabin structure on 3rd layer, is not a fancy nor new idea but could be renascent with its large allowance of battery compartment in 2nd layer for car designers, which means perfect elasticity for car Makes to launch face-lifts or model changes transformed from hybrid to hydrogen-fuel cell or PEV with reasonable cost, continuing product image, as well as customer convenience. More than that, the flat cabin floor and maximized space from sandwich body-chassis issue some other incentives for buyers. C. Collaborations across Makes, industries and countries for setting up the technique and homologation standards regarding cell specifications, packaging, working voltage, ampere, durability, safety requirement, etc.. More globalized standard means greater economic scale of car-power batteries, thus suppliers and developers are dare to invest and research new choices for positive pole and negative pole with more discharging watt, safer and costless over-heat interruption, prevention treatment, etc., which will turn the clock earlier for implementing battery cross over power density of 300 Wh/kg and rechargeable life of 3,000 times. D. Fights for lithium and rare-earth elements such as neodymium seen in ‘king of permanent magnet Nd2Fe14B’ , dysprosium for reducing magnet weight by 90%, lanthanum applied in piezoelectric, radiator, reluctance, and hydrogen-storage alloy, cerium as a treatment ingredient in catalyst converter and additives in UV-cut as well as insulator glasses by its peculiarity of absorbing ultraviolet and infrared. Lithium and rare-earth elements are not rare on earth, but for these minerals already used in plenty of industries, their supplies and prices will be a disaster when automotive industry transmutes itself an electricity-driven Tyrannosaurus Rex swallowing lithium and rare-earth elements everywhere. Furthermore, supply stability would be critical politic risks due to 50% of these minerals are excavated and shipped out from Bolivia and China . Perhaps couple years later, some automotive groups will learn a lesson from Ford hundred years ago to buy out mine fields as their own. E. Compulsory notation of carbon footprints covering vehicle’s raw-material input, manufacturing, assembly and transportation. Besides of safety, comfort, horsepower, fuel-saving and price-value items, customers would be educated or encouraged to consider the environment-friendly issues of the Makes and models in their choosing basket. On the other hand, lean carbon-footprint production usually co-exists with energy saving and potentiality of cost down. It benefits automotive manufacturers in some way and also indicates lower resistance against this kind of the policy. F. Popularity of bio-fuels, however, bio-ethanol might wipe out bio-diesel eventually. The crux happens that the raw materials of starch-esterified bio-diesel come from plant seeds, these economic plants for bio-diesel and food plants repel each other, it has been proven that some food shortage occurred. On the contrary the protein-esterified bio-ethanol, distilled from the waste of food plant such as corn branch, seems much harmless to food supply. Global popularity of bio-fuels will not happen until mature hybrid system fitted with constant-rpm-engine generator, likely late 2010’ s. The simplified and light-burden engine asks fuels for less clarity and reliability, which seen in bio-fuels, and probably works with multi fuels via viscosity compensator just like the system in former military trucks. It allows bio-fuels replacing quite a percentage of fossil fuels by lower abstraction cost and competitive price. In case of running out of fuel on road at that day, you might have a bottle of salad oil in nearby grocery store but not a faraway gas station, feed the tank and drive your car away. G. Legal obligation for car manufacturers and import distributors to recycle their vehicles delivered. Enhancing efficiency and value is tough for an irrelevant and layman recycle-industry dealing with hundreds of car Makes and models and over 10 thousands components each unit. Recycling undertaken by car Makes meets polluter-pays justice, leaves the decoding, detaching, extraction, reuse and resale works to the experts who own all the secrets regarding part compositions and assembly puzzles. Besides this polluter-pays mechanism no only forces car Makes to include recycling cost and revenue from early design and development end, but also rescues and reutilizes the factories, facilities and employees idled from blind expansions globally in last decade. The all-important point is a win-win effect between car Makes and customers when energy-saving and earth-evergreen vehicles convince customers keeping to replace their old ones and even purchasing additional new cars without pressures or extra cost from environment protection regulations. Good days will quite likely come in 2010’ s, sooner or later. Early birds capturing the downwind will survive and grow, late movers might be buried in history. Mayorders and insight give to automotive-industry winners, as well as benefit society and this planet.

|

|

| ( 時事評論|公共議題 ) |