字體:小 中 大

字體:小 中 大 |

|

|

|

| 2010/03/28 10:06:44瀏覽1852|回應3|推薦9 | |

The correct title of this topic is An X-bar and R chart is a pair of control charts used with processes that have a subgroup size of two or more. The standard chart for variables data, X-bar and R charts help determine if a process is stable and predictable. Always look at the Range chart first. There should be more than five distinct values plotted, and no one value should appear more than 25% of the time. If there are values repeated too often, then you have inadequate resolution of your measurements, which will adversely affect your control limit calculations. After reviewing the Range chart, interpret the points on the X-bar chart relative to the control limits. Never consider the points on the X-bar chart relative to specifications, since the observations from the process vary much more than the subgroup averages. a. Calculate the average range (Rbar):

where k is the number of subgroups.

d. Plot Xdbar on the Xbar chart as a solid line and label.

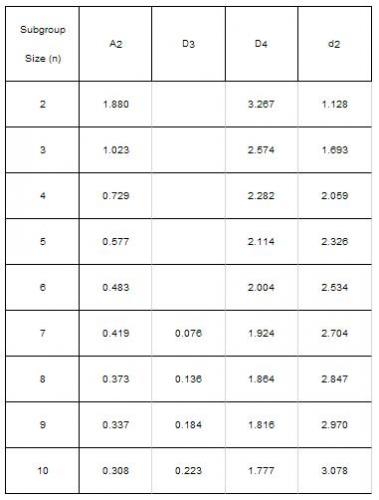

where D4, D3, are control chart constants that depend on subgroup size (see the table below).

h. Plot the control limits on the Xbar chart as dashed lines and label. If the R chart is in statistical control, the process standard deviation, s, can be calculated as: s=Rbar/d2 where d2 is a control chart constant that depends on subgroup size (see the table below). To calculate control limits and to estimate the process standard deviation, you must use the control chart constants D4, D3, A2, and d2. These control chart constants depend on the subgroup size (n). These control chart constants are summarized in the table below. For example, if your subgroup is 4, then D4 = 2.282, A2 = 0.729, and d2 = 2.059. There is no value for D3. This simply means that the R chart has no lower control limit when the subgroup size is 4. 平均數-全距管制圖(X-bar R Chart)

|

|

| ( 知識學習|科學百科 ) |

and R chart. R means Range here.

and R chart. R means Range here.