字體:小 中 大

字體:小 中 大 |

|

|

|

| 2024/08/01 15:53:11瀏覽105|回應0|推薦0 | |

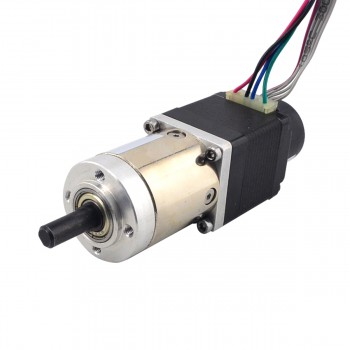

1.Definition of stepper motor encoders

A stepper motor encoder is a device used to measure the rotational position and speed of a motor, and its principle is similar to that of a photoelectric encoder. A stepper motor encoder usually consists of two parts: a fixed Hall element and a magnetic element fixed to the rotating shaft. When the rotating shaft drives the magnetic element to rotate, it passes through the Hall element, which measures the strength and direction of the magnetic field and converts it into an electrical signal. By processing and analyzing the electrical signal, the rotational position and speed of the stepper motor can be obtained.

2.Differences in the materials of stepper motor encoders

1.Photoelectric encoders mainly use photoelectric sensors and encoder discs to measure the position and movement of the rotor. Its working principle is to sense the grating or encoding holes on the encoder disc through photoelectric sensors, thereby measuring the angle and position of the rotor. Photoelectric encoders are widely used in stepper servo motor systems that require high-precision position measurement. They have the characteristics of high resolution and high precision, but may be affected by dust, grease and other contaminants.

2.Magnetic encoders use magnetic sensors and magnetic scales to detect the position and movement of the rotor. It uses the interaction between the magnetic strip on the magnetic scale and the magnetic sensor to achieve angle and position measurement. Magnetic encoders are suitable for stepper servo motor systems that have certain requirements for accuracy and stability. Although it may not be as affected by pollution as photoelectric encoders, it still performs well in high-precision applications.

3.Functions of stepper motor encoders

1.Real-time display of current absolute position: The encoder can display the current absolute position of the stepper motor in real time, which is very important for applications that require precise position control.

2.Real-time display of incremental angle: In addition to displaying the current position, the encoder can also display the incremental angle of motor rotation, which is very useful for applications that require precise control of the motor rotation angle.

3.Automatically set the initial zero position: When the motor is powered on, the encoder can automatically set the current position to the initial zero position, which is very convenient for applications that need to start from a known starting point.

4.Speed measurement function: By calculating the position difference between two times divided by time, the real-time speed of the motor can be measured, which is very useful for applications that require precise control of the motor speed.

4.Maintenance methods for stepper motors

1.Regular inspection: Regularly inspect the mechanical part of the encoder, generally once a month, mainly to check whether the mechanical connection points are misaligned to ensure its normal working state.

2.Cleaning: The encoder should be cleaned on time, and high-quality conductive agents should be used for cleaning. Be careful to operate gently and try to avoid contact with the internal components of the encoder.

3.Timely replacement of wearing parts: Regularly inspect and test the encoder, and replace wearing parts such as cables, rotors, contactors, etc. in a timely manner to ensure the normal operation of the encoder.

4.Comprehensive inspection and calibration: Regularly conduct comprehensive inspection and calibration of the encoders lines, links, signal sources and power consumption to keep the encoder signal accurate, stable and high-precision.

5.Pay attention to maintenance and management: Take effective measures to maintain and manage the encoder to avoid long-term lurking in the machine, resulting in irreversible damage such as loosening, aging or wear and deformation. In particular, pay attention to the maintenance and activation of unused encoders for a certain period of time.

5.Summary

The function of the stepper motor encoder is to provide precise positioning and feedback information for the control system, which can not only improve the accuracy and performance of the stepper motor, but also improve the reliability and stability of the system. According to the actual control needs, different types of encoders can be selected to realize the control of the stepper motor.

|

|

| ( 不分類|不分類 ) |