字體:小 中 大

字體:小 中 大 |

|

|

|

| 2021/04/13 08:48:44瀏覽37|回應0|推薦0 | |

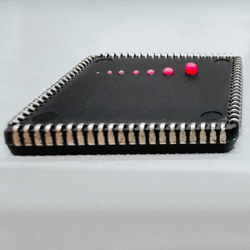

Supply electronic components,provide globle service 1521384 In stock, please contact and get the pricing and Lead time . https://www.oemsnavi.com/en/ProductDetail/1521384 New die attach adhesive for semiconductor and SMT applications20-08-2020 | DELO | Subs & Systems DELO has released a new die attach adhesive to replace the previous MONOPOX MK096. The adhesive features high strength even after ageing and can be dispensed yet more precisely than its predecessor. This has been proved in tests together with the machine integrator ASM Assembly Systems. The fluorescent adhesive is ideal for long-term usage in a broad range of applications. Like its predecessor, it is a heat-curing one-component epoxy resin. The new adhesive displays a 150% higher strength after seven days of storage at 85% relative air humidity and a temperature of +85C. It keeps its strong adhesion even after typical ageing tests, such as the MSL1 test, in accordance with JEDEC standard. When using 1mm x 1mm2 silicon dies, the test revealed adhesion values of 47N on FR4 substrate and 62N on gold. Are you still worried about not finding some scarce electronic parts ? As an independent distributor of electronic components, OemsNavi.com has established a strong relationship with the manufacturers and world-famous agents. OemsNavi.com is focusing on selling various types of discrete semiconductor devices, supporting customers to order samples, providing great convenience for all types of manufacturers, research institutions, universities, engineers, electronics enthusiasts. OemsNavi.com consistently upholds the concepts of customer first, quality first and reputation first, maximizing customer’s needs and optimizing customer’s efforts. OemsNavi.com SPECIALIZES IN…

Curing occurs at +130C in ten minutes. The fluorescent adhesive is offered in 10cc cartridges and can be ordered in quantities of just one. Once opened, the product can be used in a user-friendly way for up to seven days in a regular climate of +23C.

About UsOEMSNAVI is an online e-commerce platform belongs to PNEDA Technology Co., Ltd (Hong Kong). United with global components distributors and in-stocked inventory suppliers, we are committed to providing convenient purchase experiences and high quality services. OEMSNAVI has offices in both Hong Kong and Shenzhen, We are a professional agent of electronic components distributor with many years of industry experience, especially in the passive component area. Passive Components construct the base of the modern industry. We are proud to supply all kinds of the passive components such as a full range of Capacitors, Crystals, Oscillators, Resonators, Filters, Inductors, Coils, Chokes, Potentiometers and Resistors with the famous brands such as AD, AVX, Cypress, Infineon, KEMET, Littelfuse, Murata, Panasonic, Samsung, TDK, Toshiba, Yageo and more other brands. |

|

| ( 不分類|不分類 ) |